86 13850031815

89636303@qq.com

彩板波纹金属屋面瓦辊压成型机

- 金属波纹瓦成型机采用手动预切刀切断料头尾部,18工位成型,并配有网格式安全罩。

- 原产地:China

港口:Xiamen, China

材料厚度: 0.4-0.6mm

材料宽度: 1250mm

覆盖宽度: 1020mm

成型道次: 18 Station

电机功率: 7.5KW

轴直径: 75/95mm

辊轮材质: 45# Steel Coated With Hard Chrome

切割刀片类型: Cr12

PLC品牌: Simenz - Contact Us

彩板波纹金属屋面瓦辊压成型机

高质量高速金属波纹瓦片成型机是对钢板进行连续轧制和冷成型的专用设备。 它采用卷取钢板为原材料,经重卷、连轧、冷成型,自动切割成所需的尺寸和规格,输出成品板材。 该设备采用PLC控制、交流变频调速技术,实现连续自动生产,是一种新型节能高效的钢结构生产设备。

整条金属波纹板成型机生产线选用液压压制/切割装置,切割刀片由Cr12材料制成,装置由泵电机驱动,所有动作由PLC控制系统控制。

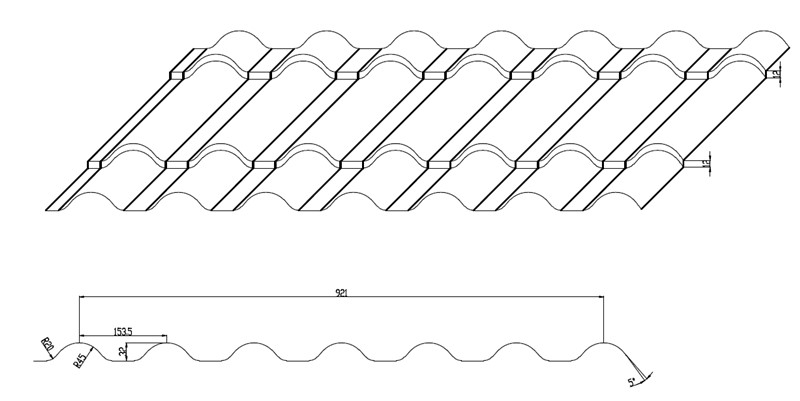

下面是该波纹瓦片成型机的瓦设计图,原材料为1250mm宽度的铝板,适合材料厚度为0.4-0.6mm,六波,最大瓦深度为15mm。

技术参数

|

Parameters |

Specification |

|

Voltage |

380V/50HZ/3PH/or customized |

|

Driving Motor |

7.5KW |

|

Forming Steps |

18 steps |

|

Working Speed |

3-4m/min |

|

Thickness for Steel |

0.3-0.7mm (Material:aluminum) |

|

Shaft Diameter |

75/95mm |

|

Shaft Material |

High grade 45# forged steel |

|

Roller Material |

G45# steel, CNC lathe,polished and chrome plated |

|

PLC Cabinet |

Schneider, Simenz |

|

Encoder |

Omron |

|

Sprocket Wheel |

45 steel high-frequencies quench |

|

Cut-off System |

Post cutting, no waste cutting |

|

Cutting Blade Material |

Cr12 steel |

|

Machine Frame Material |

Fine welded structural steel; |

|

Roofing Material |

Aluminum sheet |

|

Painted Color |

Blue+Orange Or Customization |

|

Overall Size |

180000*1550*1650mm |

|

Weight |

9500KGS |

- 上一篇 : 钢金属楼承板成型机

- 下一篇 : 飞切波纹瓦成型机博工

- 联系我们

- 厦门市集美区集美北大道788-5D

- 86 13850031815

- 86 13850031815

- 89636303@qq.com

- 89636303@qq.com

- 86 13850031815

- 86 13850031815

Chinese

Chinese